16-2000mm PE yeeb nkab extrusion kab

Daim ntawv thov

HDPE yeeb nkab kab yas yog siv los ua txhua yam ntawm HDPE kav, xws li: cov dej ua liaj ua teb & tso cov kav dej, cov khoom siv dej hauv vaj tse & cov kav dej tso tawm, cov kav dej xa dej, thiab lwm yam.

Cov kav dej siab

Kev xa dej thiab kev thauj mus los kav

Gas faib thiab kev thauj mus los kav

Mine field pipes

Cov kav dej ua liaj ua teb

Tshem tawm cov kav dej rau cov khoom siv tshuaj thiab zaub mov

Kev tiv thaiv thiab cov kav dej rau hluav taws xob cables thiab kev sib txuas lus

Fishpond ntug guardrail kav

Kev piav qhia

Hdpe yeeb nkab kab tshuab muaj hdpe yeeb nkab extruder tshuab, yeeb nkab tuag, calibration units, txias tank, haul-off, cutter, stacker / coiler thiab tag nrho cov peripherals.

Hdpe yas yeeb nkab extrusion kab tsim cov kav dej nrog txoj kab uas hla ntawm 20 mus rau 1600mm nyob rau hauv ntau yam khoom, xws li HDPE, PP-H thiab lwm yam.type specimen book.

Hdpe yeeb nkab tshuab yog ib qho kev nyiam rau kev ua haujlwm ntawm cov pa roj, cov kav dej thiab cov kav dej ua liaj ua teb ntawm lub nroog thiab lub zos.

Yeeb Nkab Tankflow Daim Ntawv Qhia ntawm Hdpe Yeeb Nkab Extrusion Kab

Raw khoom + additive → mixing → nqus tsev noj mov → hopper tshuab → ib leeg ntsia hlau extruder → xim band extruder → pwm thiab calibrator → nqus calibration tshuab → txias tank → haul-off tshuab → txiav tshuab → stacker (Winding tshuab)

Nta thiab Qhov Zoo

1. PE yeeb nkab ua tshuab yog tsim los ntawm Polestar raws li European advanced technology thiab R & D kev ntawm yas machinery rau ntau xyoo, advanced tsim, tsim nyog qauv, muaj kev ntseeg siab, high degree automation ntawm hdpe yeeb nkab ntau lawm kab.

2. Extruder nrog tshwj xeeb barrel pub qauv tuaj yeem txhim kho lub peev xwm extrusion.

3. Kev tswj qhov kub thiab txias, zoo plasticization, kev ua haujlwm ruaj khov.

4. PE yeeb nkab ntau lawm kab adopts PLC tswj system, realizing synchronization thiab automation.

5. Tib neeg-lub computer interface yog yooj yim rau kev khiav lag luam, yooj yim thiab txhim khu kev qha.

6. Kauv thiab lattice pob tawb hom tuag tuag rau kev xaiv.

7. Hloov qee qhov ntawm txoj kab tuaj yeem paub txog ob txheej thiab ntau txheej co-extrusion.

8. Hloov qee qhov ntawm cov kab kuj tuaj yeem tsim cov kav dej PP, PB.

Technical Data

| Qauv | Cov kav dej ntau (mm) | Extruder | Tuag taub hau | Tag nrho lub zog (kW) | Tso zis muaj peev xwm (kg / h) |

| PEB-63 | 16-63 : kuv | SJ 65 | Ib qhov hluav taws xob | 100 | 80-120 : kuv |

| PEB-110 | 20-110 : kuv | SJ 65 | Ib qhov hluav taws xob | 150 | 150-250 |

| PEB-160 | 50-160 : kuv | SJ 75 | Ib qhov hluav taws xob | 180 | 150-250 |

| PEB-250 | 75-250 : kuv | SJ 75 | Ib qhov hluav taws xob | 230 | 250-350 |

| PEB-450 | 160-450 Nws | SJ 90 | Ib qhov hluav taws xob | 380 | 350-450 : kuv |

| PEB-630 | 250-630 Nws | SJ 120 | Ib qhov hluav taws xob | 550 | 700-800 Nws |

| PEB-800 | 500-800 | SJ 150 | Ib qhov hluav taws xob | 800 | 900-1100 Nws |

| PEB-1200 | 710-1200 Nws | SJ 150 | Ib qhov hluav taws xob | 1000 | 1000-1300 Nws |

| PEB-1600 | 1000-1600 Nws | SJ 150 | Ib qhov hluav taws xob | 1200 | 1200-1500 Nws |

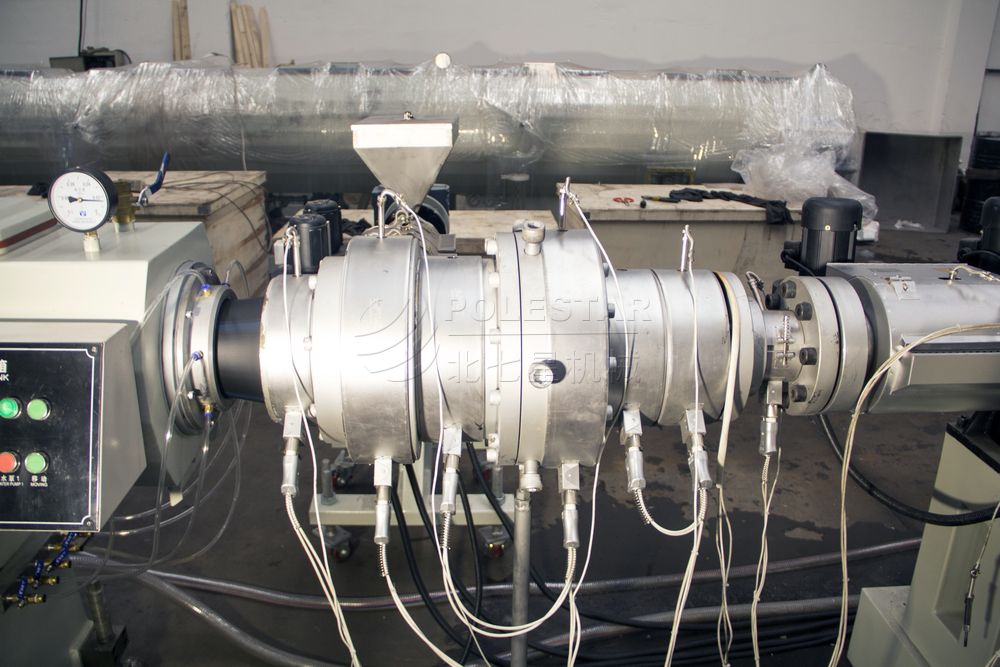

Ib leeg ntsia hlau Extruder

Raws li 33: 1 L / D piv rau cov ntsia hlau tsim, peb tau tsim 38: 1 L / D ratio.Piv nrog rau 33: 1 piv, 38: 1 piv muaj qhov zoo ntawm 100% plasticization, ua kom cov zis muaj peev xwm los ntawm 30%, txo hwj chim noj mus txog 30% thiab ncav cuag yuav luag linear extrusion kev ua tau zoo.

Simens Kov Screen thiab PLC

Thov kev pab cuam tsim los ntawm peb lub tuam txhab, muaj lus Askiv los yog lwm yam lus los muab tswv yim rau hauv lub system.

Spiral Structure ntawm chim

Pub ib feem ntawm lub thoob siv kauv qauv, los xyuas kom meej cov khoom noj nyob rau hauv ruaj khov thiab kuj nce pub muaj peev xwm.

Tsim tshwj xeeb ntawm Screw

Ntsia hlau yog tsim los nrog cov qauv tshwj xeeb, kom ntseeg tau tias zoo plasticization thiab sib tov.Unmelted khoom tsis tuaj yeem hla qhov no ntawm cov ntsia hlau.

Cua Txias Ceramic rhaub

Ceramic rhaub kom lub neej ua haujlwm ntev.Qhov kev tsim no yog txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau nws, nws yuav tsum tau txiav txim siab nws yuav tsum tau txiav txim siab, nws yog qhov tsim nyog yuav tsum tau ua tib zoo saib xyuas cov nroj tsuag, cov nroj tsuag yuav tsum tau muab pov tseg.Ua kom muaj cua txias zoo dua.

Siab Zoo Gearbox

Iav raug kom ntseeg tau 5-6 qib thiab qis suab nrov qis dua 75dB.Compact qauv tab sis nrog siab torque.

Extrusion Tuag Lub Taub Hau

Extrusion tuag taub hau siv kauv qauv, txhua yam khoom ntws channel tau muab tso rau sib npaug.Txhua channel yog tom qab kev kho cua sov thiab daim iav polishing kom ntseeg tau tias cov khoom ntws zoo.Tuag lub taub hau qauv yog compact thiab kuj muab ruaj khov siab, ib txwm los ntawm 19 mus rau 20Mpa.Nyob rau hauv lub siab no, cov yeeb nkab zoo yog qhov zoo thiab tsis tshua muaj kev cuam tshuam rau cov zis muaj peev xwm.Muaj peev xwm tsim ib txheej lossis ntau txheej yeeb nkab.

Tsiv Ntaus ntawm Tuag Lub Taub Hau

Rau qhov loj loj tuag lub taub hau, cov cuab yeej txav tau txav tau lub taub hau tuag rau pem hauv ntej thiab rov qab, kuj kho qhov siab ntawm lub taub hau tuag.Kev khiav hauj lwm yog ceev thiab yooj yim.

Tuag Head Rotary Device

Rau qhov loj loj tuag lub taub hau nrog cov khoom siv teb, lub taub hau tuag tuaj yeem tig los ntawm 90 degree.Thaum hloov bush, mandrel, tuag lub taub hau yuav tig 90 degree.Yuav siv crane nqa thiab hloov hav txwv yeem thiab mandrel.Txoj kev no yooj yim heev.

Thaum tshav kub kub Exhausting Device

Cov cuab yeej no ntxiv rau ntawm lub taub hau tuag los tsim cov yeeb nkab loj thiab tuab.Txhawm rau tso cua sov hauv cov yeeb nkab thiab cov yeeb nkab txias hauv phab ntsa.Cov cua sov uas siv tau tuaj yeem siv los ziab cov khoom siv raw.

Cov Cuab Yeej Cuab Yeej rau Core

Thaum tsim cov yeeb nkab nrog lub taub loj thiab phab ntsa tuab, peb yuav siv cov dej txias lossis roj ua ke nrog cov kiv cua txias kom txias cov tub ntxhais ntawm lub taub hau tuag kom tsis txhob muaj cua sov thiab ua kom cov khoom zoo.

Nqus Tank

Lub tshuab nqus tsev vacuum yog siv los tsim thiab txias yeeb nkab, thiaj li ncav cuag tus qauv yeeb nkab loj.Peb siv ob chav chamber qauv.Thawj chav yog nyob rau hauv luv luv, kom ntseeg tau tias muaj zog heev txias thiab lub tshuab nqus tsev muaj nuj nqi.Raws li calibrator tau muab tso rau hauv pem hauv ntej ntawm thawj chamber thiab cov yeeb nkab zoo yog tsim los ntawm calibrator, qhov kev tsim no tuaj yeem ua kom sai thiab zoo dua tsim thiab txias ntawm cov yeeb nkab.

Muaj zog txias rau Calibrator

Nrog tshwj xeeb cua txias system rau calibrator, uas tuaj yeem ua kom txias txias zoo rau cov yeeb nkab thiab xyuas kom muaj kev kub ceev.Tsis tas li nrog cov tshuaj tsuag zoo zoo kom muaj qhov ua kom txias zoo dua thiab tsis yooj yim thaiv los ntawm impurities.

Kev them nyiaj yug zoo dua rau cov yeeb nkab

Rau cov yeeb nkab loj loj, txhua qhov loj muaj nws tus kheej semicircular txhawb phaj.Cov qauv no tuaj yeem khaws cov yeeb nkab roundness zoo heev.

Silencer

Peb muab cov twj tso kua mis tso rau ntawm lub tshuab nqus tsev kho kom txo qis suab nrov thaum huab cua nkag rau hauv lub tshuab nqus tsev.

Siab Relief Valve

Txhawm rau tiv thaiv lub tshuab nqus tsev.Thaum lub tshuab nqus tsev kawm ntawv ncav cuag qhov kev txwv siab tshaj plaws, lub valve yuav qhib cia li txo qis lub tshuab nqus tsev kom tsis txhob tawg ntawm lub tank.Lub tshuab nqus tsev degree txwv tuaj yeem hloov kho.

Ob Chav Loop Pipeline

Txhua lub voj nrog cov dej lim dej, muab cov dej huv huv hauv lub tank.Ob lub voj kuj tseem xyuas kom muaj cov dej txias hauv lub tank tas mus li.

Dej, Gas Separator

Txhawm rau cais cov roj av dej.Gas tawm ntawm upside.Cov dej ntws mus rau hauv lub downside.

Tag Nrho Tsis Siv Neeg Dej Tswj

Nrog kev tswj qhov kub thiab txias kom muaj qhov tseeb thiab ruaj khov ntawm cov dej kub.

Tag nrho cov dej inlet thiab qhov hluav taws xob yog tswj tag nrho tsis siv neeg, ruaj khov thiab txhim khu kev qha.

Centralized Drainage Device

Tag nrho cov dej ntws los ntawm lub tshuab nqus tsev vacuum yog kev sib xyaw thiab txuas rau hauv ib lub kav dej stainless.Tsuas yog txuas cov kav dej sib xyaw ua ke rau cov dej ntws tawm sab nraud, kom ua haujlwm yooj yim dua thiab nrawm dua.

Lub tank txias

Lub tank txias yog siv los txias cov yeeb nkab ntxiv.

Yeeb Nkab Clamping Device

Cov cuab yeej no tuaj yeem kho cov yeeb nkab roundness thaum cov yeeb nkab tawm los ntawm lub tshuab nqus tsev.

Dej Tank Lim

Nrog lim hauv lub tank dej, kom tsis txhob muaj cov impurities loj thaum cov dej sab nraud tuaj.

Zoo Txau Nozzle

Cov tshuaj tsuag zoo zoo muaj qhov ua kom txias zoo dua thiab tsis yooj yim thaiv los ntawm impurities.

Yeeb Nkab Txhawb Kev Kho Khoom Siv

Kev them nyiaj yug nrog kev hloov ua haujlwm los txhawb cov yeeb nkab nrog cov kab sib txawv.

Yeeb Nkab Txhawb Ntaus

Tshwj xeeb tshaj yog siv thaum tsim cov yeeb nkab nrog loj txoj kab uas hla thiab phab ntsa thickness.Cov cuab yeej no yuav muab kev txhawb nqa ntxiv rau cov kav dej hnyav.

Haul Off Unit

Haul off unit muab txaus traction quab yuam los rub cov yeeb nkab stably.Raws li cov yeeb nkab sib txawv qhov ntau thiab tsawg, peb lub tuam txhab yuav hloov kho traction ceev, tus naj npawb ntawm claws, zoo traction ntev.Txhawm rau kom phim cov yeeb nkab extrusion ceev thiab sib sau ceev, kuj tsis txhob deformation ntawm cov yeeb nkab thaum traction.

Sib cais Traction Motor

Txhua lub claw muaj nws tus kheej traction lub cev muaj zog, nyob rau hauv cov ntaub ntawv thaum ib tug traction motor nres ua hauj lwm, lwm yam motors tseem yuav ua hauj lwm.Muaj peev xwm xaiv servo lub cev muaj zog kom muaj zog traction loj, ruaj khov traction ceev thiab ntau yam ntawm traction ceev.

Claw Adjustment Device

Tag nrho cov claws yog txuas rau ib leeg, thaum kho txoj hauj lwm ntawm claws kom rub cov yeeb nkab hauv qhov ntau thiab tsawg, txhua claws yuav txav mus ua ke.Qhov no yuav ua rau kev ua haujlwm sai thiab yooj yim dua.

Tus neeg siv tus phooj ywg tsim

Nrog Siemens hardware thiab cov neeg siv khoom phooj ywg software tsim los ntawm peb lub tuam txhab.Muaj kev ua haujlwm synchronized nrog extruder, ua haujlwm yooj yim dua thiab sai dua.Tsis tas li cov neeg siv khoom tuaj yeem xaiv tsuas yog qee qhov claws los ua haujlwm los rub cov kav dej me me.

Cais Cua Siab Tswj

Txhua claw nrog nws tus kheej huab cua tswj, muaj tseeb dua, kev ua haujlwm yooj yim dua.

Cutter

Cutter tswj los ntawm Siemens PLC, ua hauj lwm ua ke nrog nqa tawm tsev kom muaj meej txiav.Cov neeg siv khoom tuaj yeem tsim qhov ntev ntawm cov yeeb nkab uas lawv xav txiav.Multi-feed-hauv kev ua rau kev ua tiav ntawm ib txoj kev txiav (tiv thaiv cov hniav thiab saws, tiv thaiv cov hniav thiab saws daig rau cov yeeb nkab tuab thiab txiav lub ntsej muag ntawm cov yeeb nkab yog du).

Universal Clamping Device

Siv cov cuab yeej clamping thoob ntiaj teb rau cov yeeb nkab sib txawv, tsis tas yuav hloov cov khoom siv clamping thaum cov yeeb nkab loj hloov.

Pom thiab Hniav Interchangeable

Qee cov cutters yog nruab nrog ob qho tib si saw thiab hniav.Pom thiab hniav txiav yog interchangeable rau cov yeeb nkab sib txawv.Tsis tas li ntawd, saws thiab hniav tuaj yeem ua haujlwm ua ke rau qhov kev xav tau tshwj xeeb.

Kev kho qhov siab Central

Nrog hluav taws xob kho cov cuab yeej rau clamping ntaus ntawv.Kev ua haujlwm sai thiab yooj yim dua.Nrog txwv hloov kom muaj kev nyab xeeb.

Stacker

Txhawb nqa thiab tshem tawm cov kav dej.Ntev ntawm stacker tuaj yeem hloov kho.

Cov yeeb nkab nto tiv thaiv

Nrog rau cov menyuam, los tiv thaiv cov yeeb nkab nto thaum txav yeeb nkab.

Kev kho qhov siab Central

Nrog cov cuab yeej hloov kho yooj yim los kho qhov nruab nrab qhov siab rau qhov sib txawv ntawm cov yeeb nkab.

Coiler

Txhawm rau coil yeeb nkab rau hauv cov menyuam, yooj yim rau kev khaws cia thiab kev thauj mus los.Feem ntau siv rau cov yeeb nkab hauv qab qhov loj 160mm.Muaj ib qho chaw nres tsheb thiab ob qhov chaw nres tsheb rau kev xaiv.

Kev siv servo motor

Muaj peev xwm xaiv servo lub cev muaj zog rau cov yeeb nkab xa mus thiab winding, ntau qhov tseeb thiab zoo dua cov yeeb nkab xa tawm.

Cov khoom qeb

Koj puas xav ntxiv Ntuj rau koj lub hom phiaj?

Tiv tauj peb hnub no rau kev sib tham tsim.