High Efficient PPR Yeeb Nkab Extruder Tshuab

Kev piav qhia

PPR yeeb nkab extruder siv nyob rau hauv extrudering PPR, polyolefin thiab lwm yam thermoplastics.

PPR yeeb nkab extruder tuaj yeem ua tiav txhua yam ntawm cov khoom yas nrog lub tshuab pab cuam.

Xws li zaj duab xis, yeeb nkab, bar, phaj, xov, ribbon, insulating txheej ntawm cable, hollow khoom thiab hais txog. PPR yeeb nkab extruder kuj tseem siv rau hauv nplej.

PPR yeeb nkab extruder tsim yog siab heev. Nws lub peev xwm ntau lawm yog siab. Nws plasticization yog qhov zoo, thiab nws lub zog siv tsawg. PPR yeeb nkab extruder txais yuav tawv hniav lub ntsej muag ntawm iav rau kev sib kis, nws muaj qhov zoo ntawm lub suab nrov, kev ua haujlwm du, kev thauj khoom loj, kev siv lub neej ntev thiab lwm yam.

Daim ntawv thov

PPR yeeb nkab extruder feem ntau yog siv los ua cov yeeb nkab, ntawv, bar thiab lwm yam khoom yas los ntawm cov khoom siv PPR nruab nrog ntau hom tshuab thiab nqes.

Rau SJ serial ntsia hlau extruder, cov ntsia hlau txoj kab uas hla yog los ntawm 20 mus rau 200mm, thiab cov ntsia hlau L / D yog 10-40. Koj tuaj yeem xaiv hom extruder raws li koj cov khoom, specification thiab muaj peev xwm.

Cov txheej txheem pub mis siv YASKAWA, thiab cov kabmob tseem ceeb tau txais Nyiv NSK thawj qhov chaw tuaj txawv teb chaws, lub extruder yog tus nqi zoo rau cov nyiaj. peb kuj cog lus zoo heev tom qab-muag kev pab cuam.

Technical Data

| Tube txoj kab uas hla (mm) | 16-63 : kuv | 20-110 : kuv | 75-160 : kuv | 90-250 : kuv |

| Extruder | SJ 45 | SJ 60 | SJ 75 | SJ 75 |

| Lub cev muaj zog (KW) | AC 30 | dc75 ua | DC 110 | DC 110 |

| Peev xwm (KG) | 60-100 | 100-150 | 250-300 Nws | 250-300 Nws |

| Max kab ceev (m / min) | 10 | 6 | 6 | 6 |

Ib leeg ntsia hlau Extruder

Raws li 33: 1 L / D piv rau cov ntsia hlau tsim, peb tau tsim 38: 1 L / D ratio. Piv nrog rau 33: 1 piv, 38: 1 piv muaj qhov zoo ntawm 100% plasticization, ua kom cov zis muaj peev xwm los ntawm 30%, txo lub zog siv mus txog 30% thiab ncav cuag yuav luag cov kev ua haujlwm extrusion.

Simens Kov Screen thiab PLC

Thov kev pab cuam tsim los ntawm peb lub tuam txhab, muaj lus Askiv los yog lwm yam lus los muab tswv yim rau hauv lub system.

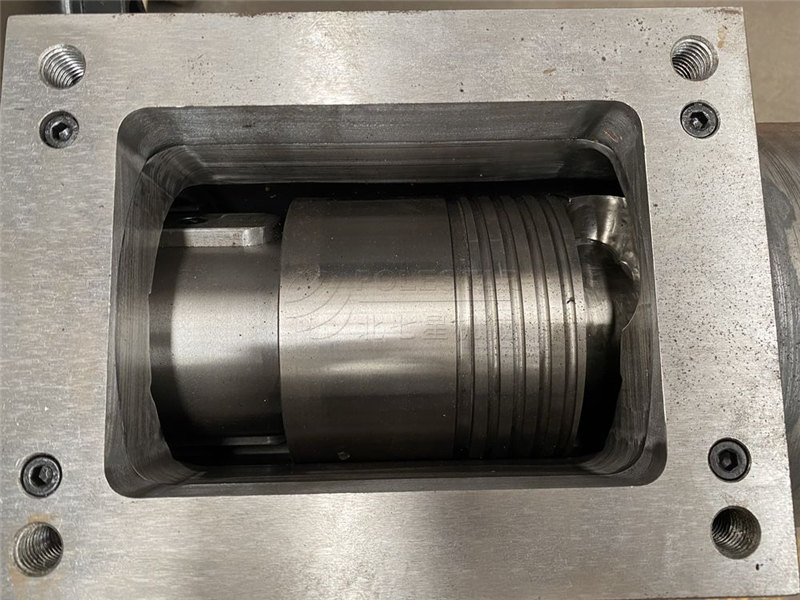

Tshwj xeeb tsim ntawm Screw

Ntsia hlau yog tsim los nrog cov qauv tshwj xeeb, kom ntseeg tau tias zoo plasticization thiab sib tov. Unmelted khoom tsis tuaj yeem hla qhov no ntawm cov ntsia hlau, zoo yas extrusion ntsia hlau.

Spiral Structure ntawm chim

Pub ib feem ntawm lub thoob siv kauv qauv, los xyuas kom meej cov khoom noj nyob rau hauv ruaj khov thiab kuj nce pub muaj peev xwm.

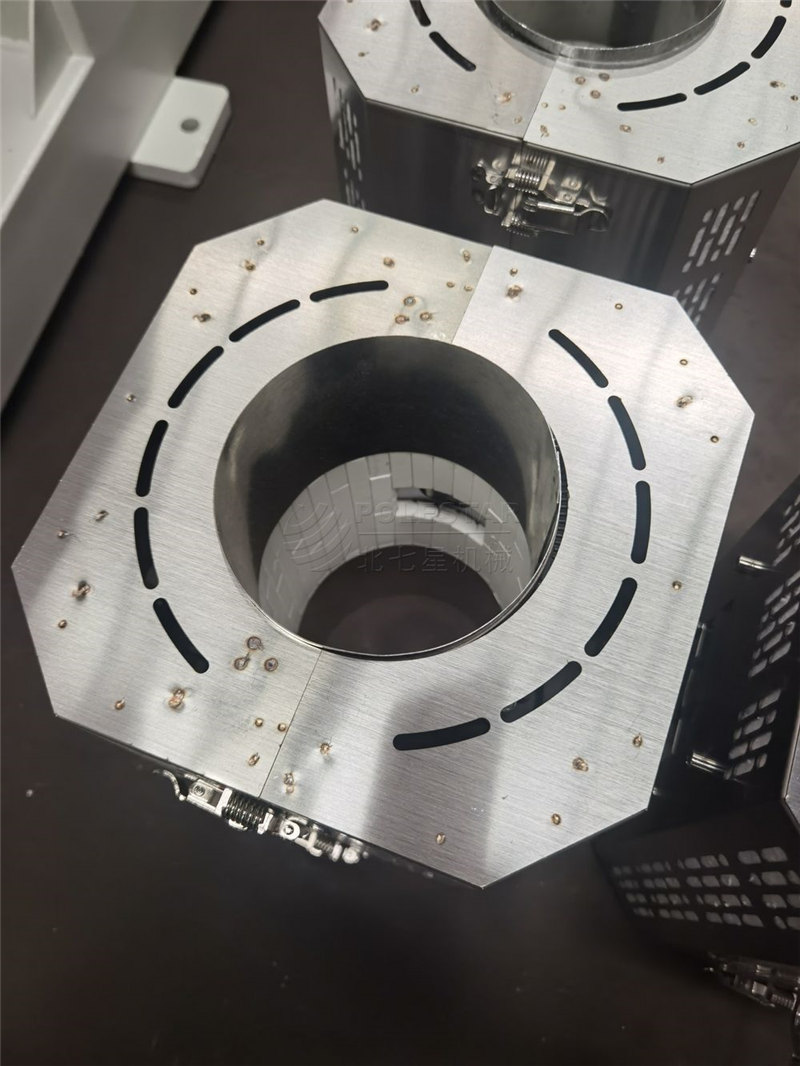

Cua Txias Ceramic rhaub

Ceramic rhaub kom lub neej ua haujlwm ntev. Qhov kev tsim no yog txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau nws, nws yuav tsum tau muab tshem tawm, nws raug nquahu kom siv cov tshuaj tua kab. Ua kom muaj cua txias zoo dua.

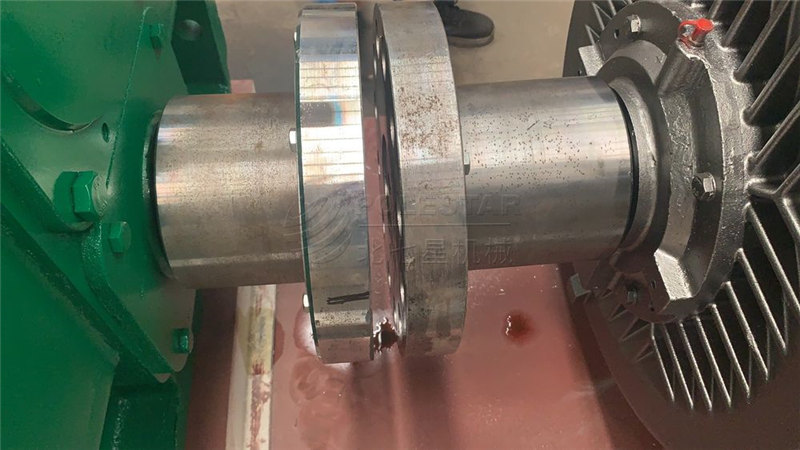

Siab Zoo Gearbox

Iav raug kom ntseeg tau 5-6 qib thiab qis suab nrov qis dua 75dB. Compact qauv tab sis nrog siab torque.

Cov khoom qeb

Xav Ntxiv Ntuj rau Koj Tsim?

Tiv tauj peb hnub no rau kev sib tham tsim.