High Efficient PET Granulating Tshuab

Yam ntxwv

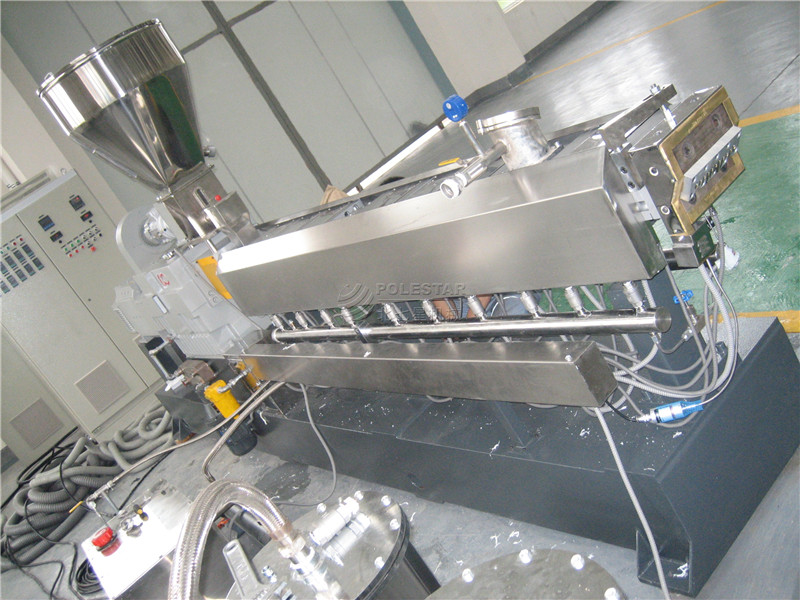

PET pelletizer yog tsim los ntawm cov khoom siv hauv qab no: extruder, hydraulic screen changer, strand txiav pwm, txias conveyor, tshuab ziab khaub ncaws, cutter, kiv cua tshuab tshuab (pub noj thiab ziab tshuab), thiab lwm yam. Siv cov ntsia hlau ntxaib ntxaib extruder kom muaj qhov kub thiab txias. , siab tso zis nrog qis zog noj.

Daim ntawv thov

Cov tsiaj pelletizing tshuab yog siv los ua PET yas flakes rau hauv pellet lossis granule.Twin ntsia hlau extruder rov siv dua & pelletizing system yog siv rau cov ntaub ntawv pov tseg, uas xav tau kev ua haujlwm siab ntawm melting, volatilization, filtering thiab lwm yam.

Txheej Txheem Flow

Screw feeder (Yeem) → Force feeder → Parallel ntxaib ntsia hlau extruder → Hydraulic lim exchanger → Pwm lub taub hau → dej txias tank → Yas txheem cutter → tiav cov khoom ntim.

Cov lus piav qhia ntxaws ntawm Txhua Yam Khoom

1. Screw Feeder: xa cov khoom yas rau hauv lub tshuab loj.

2. Force feeder: pub khoom siv rau extruder nrog kev tsim ceev, qhov ceev tuaj yeem hloov kho.

3. Parallel ntxaib ntsia hlau extruder: plasticizing khoom thiab tso pa tawm.

4. High-speed Net exchangeing system thiab Die-head: lim cov khoom impurity, kom ntau lawm ruaj khov.

5. Lub tank dej: txias rau PET noodles.

6. Yas txheem cutter: txiav PET noodles rau hauv granuels.

Competitive Advantage

1. Tsis siv neeg PLC tswj

2. Nrog tus kheej tswj qhov kub thiab txias

3. Kev ua haujlwm yooj yim & kev ua haujlwm ruaj khov

4. Ua haujlwm zoo, kev tiv thaiv ib puag ncig thiab txuag hluav taws xob

Technical Data

| Extruder | TSK 35 | TSK 50 | TSK 60 | TSK 65 | TSK 75 | TSK 95 |

| L / D (mm) | 24-56 : kuv | 24-56 : kuv | 24-56 : kuv | 24-56 : kuv | 24-56 : kuv | 24-56 : kuv |

| Max ceev (rpm) | 600 | 500 | 300-500 | 400-500 | 400-500 | 300-400 Nws |

| Lub cev muaj zog (kw) | 11-18.5 Nws | 22-37 : kuv | 37-55 : kuv | 45-75 : kuv | 90-160 : kuv | 185-250 : kuv |

| Lub zog hluav taws xob (kw) | 16 | 24 | 30 | 34 | 45 | 60 |

| Max tso zis (kg / h) | 20-80 | 50-200 | 80-300 Nws | 100-350 | 200-500 | 700-1200 Nws |

Cov khoom qeb

Xav Ntxiv Ntuj rau Koj Tsim?

Tiv tauj peb hnub no rau kev sib tham tsim.